Upverter is the “Google Docs” of printed circuit boards (PCBs), allowing multiple designers to work on the same board design simultaneously. Even the manufacturer can check in to provide real-time feedback. This Canadian startup aims to replace unruly and expensive PCB software suites like EAGLE, but Michael claims their true competition is pencil and paper, which is what he ended up using out of frustration for his fourth year design project.

Inspiration struck University of Waterloo classmates Zak Homuth, Michael Woodworth, and Stephen Hamer started Upverter almost five years ago. Zak quit his corporate job in Waterloo, told Michael in Toronto, and Steve in flew in from San Francisco. “We got drunk, real hungover the next day… We put ideas on whiteboards and somehow decided this was the best one,” says Michael. They all quit their jobs and were admitted into the Y Combinator program in California for four months. The best advice Michael got was that there are only two things to focus on: “talking to customers and building your product.”

Market Competition

All the founders worked professionally as electrical engineers and software developers, and developed a collective loathing for hardware development because they hated their tools. Michael was originally frustrated with EAGLE Professional, PCB design software that costs tens of thousands of dollars annually to own.

The next tier is Altium (about $10k), but the top three in the world are Cadence, Mentor Graphics, and Synopsys. Michael says the justification is, “If you’re going to pay an engineer a hundred thousand dollars a year–on the low end–giving them a tool for $10,000 really doesn’t matter, if it makes them any more than 10% more efficient… For a company like Apple to throw a million bucks away, they couldn’t care less. To throw a month away? That’s killer, they couldn’t possibly survive.”

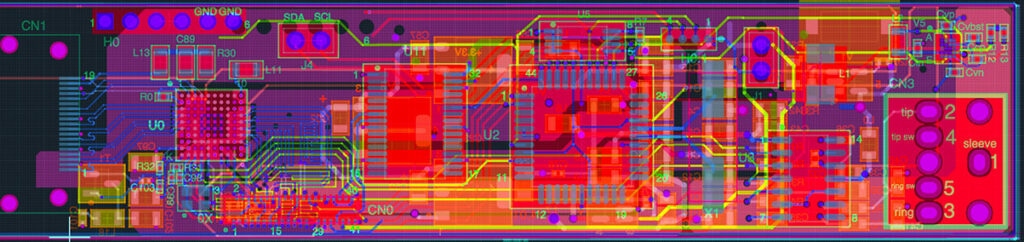

The cost of creating a prototype is also in the millions of dollars, so your tools need to help you find application-specific, niche (1000 people in the world) problems. Upverter shows us a large Revision 3 prototype board for a 10-year old fiber-optic network switch that did packet inspections (MSRP $500,000). It cost $15,000 to make and it doesn’t work. But there was also the cost of employing 12 people for 18 months, which is why hardware companies are willing to pay a lot of money to cut down even one prototype. By Revision 4, it’s usually too late.

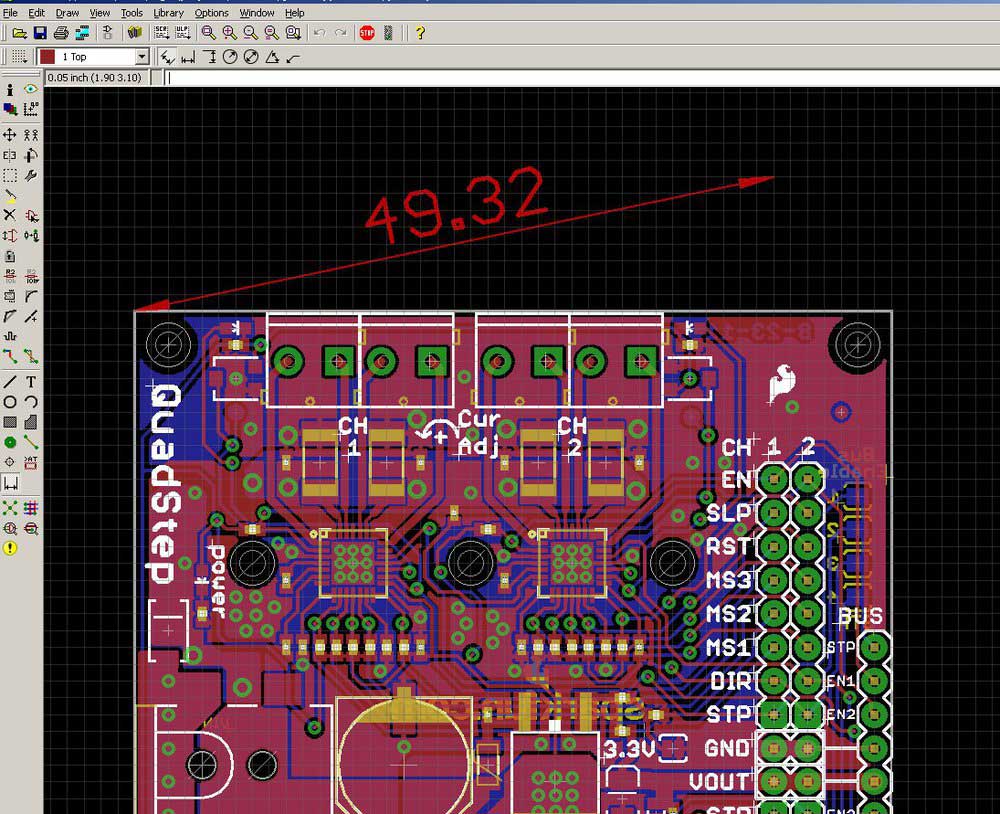

Engineering is not cut and dry. There is a 0% chance that the first prototype will work, even using software error detection. It’s a bit like how we have a building code, but even following it to the T doesn’t guarantee the safety of its occupants. Likewise in hardware engineering, you can’t predict accidental heat and manufacturing errors. In complex boards with 18 layers of copper crisscrossing, it becomes unreasonable to design with pencil and paper.

The Features

Upverter was designed for two core requirements: version control flexibility and real-time collaboration. “Version control” basically means having access to previous revisions of your file, so you can “undo” mistakes you saved to the most up-to-date version. It supports 10 engineers, so in a large design, “You could have 2 people doing schematic, 2 people working out PCB layout, 1 person dedicated to ‘dark magic radio stuff,’ 1 person worried about manufacturing, 1 person cleaning up everyone else’s mess, the actual manufacturer on there saying ‘you can’t manufacture that,’ etc.”

Adam says Upverter is resource efficient, working on mid-range Chromebooks. It’s also attractive, even though developer Carmen Yu and Michael are already working on a visual overhaul for the program.

There is also a tool generation parts library (“the largest parts library, ever,” including Sparkfun), you can make a part yourself, or you can Request a Part to be made for you. There are Arduino shield templates for the Uno. For winning over EAGLE users, Michael and Adam believe Upverter’s silver bullet is its IPC Footprint Generator.

Most importantly, Upverter takes security very seriously to maintain their users’ trust. Because of all the top-secret PCB designs in the cloud, data is stored offsite so physical access to their house “means nothing.” They patched the Heartbleed bug before Canada’s five banks did. When working with Fortune 500 companies, additional steps taken so that data doesn’t end up on developer machines.

“There are people who will spend a weekend here because of a hypothetical security concern off in the future.”

Communication & Community

“I don’t know if you know any hardware engineers. Voice chat doesn’t fly, to say the least,” they joke. Upverter uses chat rooms and Google Hangouts. Team building is board game nights and watching Futurama together over dinner. Sundays especially, there isn’t a clear delineation between lounging and working. “It’s pretty clear when people are unhappy in the office,” says Michael, “All but two employees have lived here for at least a week.”

Communicating with potential users/customers is a different story. “Our target market is possibly the hardest group to market to. Ever. It’s like trying to get a message in front of me. Or him,” says Adam. They goad EAGLE users for having Stockholm syndrome. Their marketing guy pitched an Upverter live stream: “The 4-Hour Fitbit.” Michael claims he got most of it done, minus 184 violations for “doing electrical engineering while talking to people.”

This year, Upverter is moving into the very professional market (phones, major appliances, etc.) The functionality is mostly there, in the “couple hundred thousand lines of JavaScript,” but proof is their biggest problem. “The irony is people doing really complex things ask to keep them private, and then we get judged on the open source stuff,” says Michael. Meta used Upverter to design a complex, obviously secret AR headset.

They boast a community of 40,000 users. Upverter has a partnership with University of Toronto, but they have also been talking with companies like BC electronics manufacturer Placedroid, and desktop PCB prototyping robot startups Tempo Automation and Voltera. “Pick and place” is a service where robots read a directions file, dip on average 700 tiny pins in solder, then attaches it to the board without frying the delicate chips. Traditionally, startups like Upverter end up in silicon-level semiconductor design, which is why they are looking for a workable partner.

In an exciting twist, Upverter is getting paid to use their own product, or to “eat their own dog food” as Michael put it. They have recently designed a shoe wearable and a talking toy that is currently on Kickstarter.

Sacrifices

Why do young people assume the risks of startups? “So I’m going to lose a year of my life, in my lowest-earning bracket, and learn far more than I would in a real job? The risk is pretty low. That’s how I see it. Other people don’t,” says Michael, “You get to be broke, really broke for a good, long time. That’s a fun benefit. But, the jump off the cliff wasn’t a huge deal.”

Adam’s advice is to keep being a student, because it is much harder to put work on hold for the startup experience when you’re making real money, you’ve got a nice apartment, a mortgage, and appliances. In a startup, “Netflix and gym memberships are the sacrifices you might have to make,” says Michael.

After some debate about how many people work at Upverter, they figure it’s 13. They have hired mostly through their circle of friends who know hardware, but also co-op students, and they do regular interviews for non-technical positions.

There are multiple team plans to try, but if you want to make public, open-source projects, there’s a completely free Community Edition. At this time, if you’re a student, they might even waive the non-commercialization condition for you. I feel this initiative is very big of them, and the tradeoff is more transparent than other “free” web services.

Lee Saynor is a Digital Futures undergrad at OCAD University. Before and after our field trip to New York City, the Atelier II – Collaboration class met some of the most important people and organizations in creative technology in Toronto. Thank You Michael, Adam, and Yusef!

Leave a Reply