On March 18th, we toured the Shapeways 3D printing factory in Queens, New York. This 24-hour operation allows anyone to upload a 3D model and have it printed in a wide variety of materials (55+): various plastics, rubber, full-colour sandstone, lost wax metals (outsourced): gold, silver, platinum, steel, and porcelain with food-safe glaze. Their scale and success puts them in a position to get beta access to new materials like Full-Colour Nylon by Hewlett-Packard as the technology is developed.

Who’s using Shapeways? Artists, jewelers, product designers, engineers, and you! Although seasoned modelers are printing detailed figurines, gadget accessories, drone parts, and even prosthetics, anyone can use the Etsy-like 3D model shop to get something unique while supporting the community. She uses the example of independent video game developers using Shapeways for small batch merchandising (eg. Kerbal Space Program, in Full Colour Sandstone.) Eleanor’s job is to support the Shapeways Community through social media, physical meetups, and trade shows.

Shapeways isn’t your average startup, founded in the Netherlands in 2007 by Phillips electronics designers Peter Weijmarshausen, Robert Schouwenburg, and Marleen Vogelaar. Support through the Philips Lifestyle Incubator program allowed them to open a factory in Eindhoven. They declared independence in 2010 and moved their headquarters to Queens, New York, while maintaining the original factory for fulfillment in Europe.

From Upload to Prep-Work

Shapeways is developing automated systems to drive down the cost and wait times involved with custom-order 3D printing. Printer speed is a constant, but they are always looking for ways to accelerate their pre- and post-production processes.

Before production, new improvements in model verification tools (3D Tools, clearer design guidelines) on their website make checking for common problems automated and instantaneous. Eleanor says problems usually arise in the translation of surface modeling–used in video games and movies–to the solid models of the industrial design and 3D printing world. Plug-and-play options like TinkerCAD exist, allowing you to design for 3D printing from the start.

One of the manual checks and balances is screening out jobs that that don’t meet design guidelines, like intellectual property, functional weapon parts, and pornographic items. Eleanor is confident in her team’s ability to identify the subtlest offenders.

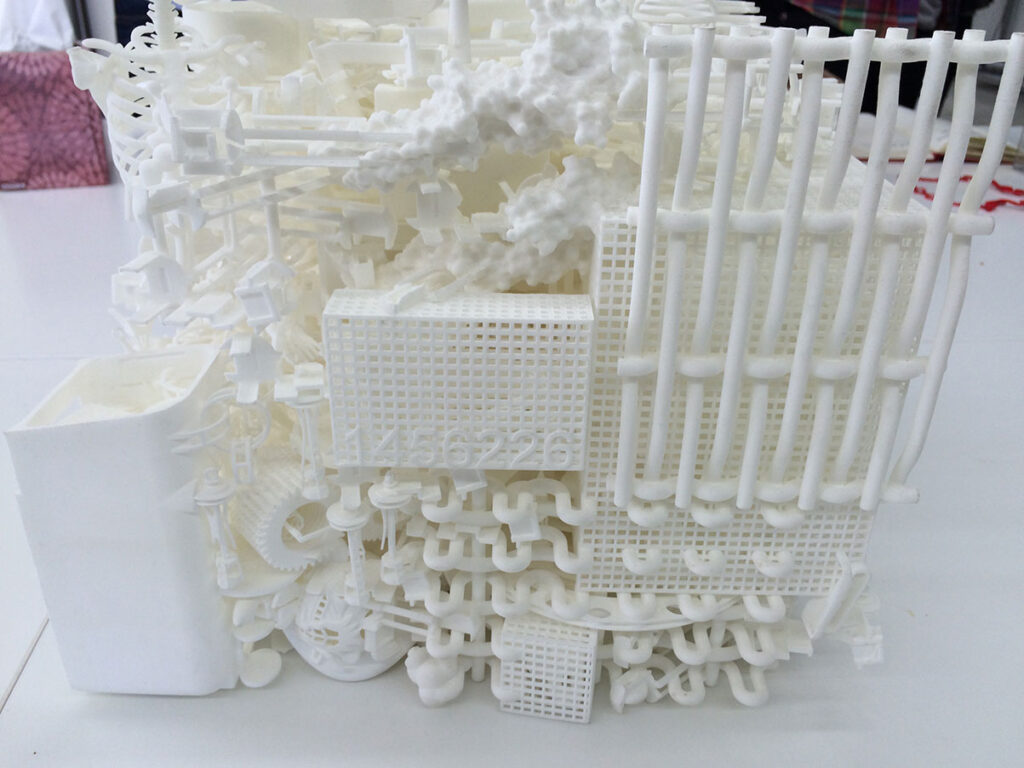

A “build” is a ready-to-print file that looks like a toy box or a game of Tetris: all designs of the same material stacked into one job using Netfabb, to run the machine most efficiently. Their custom software, InShape, is used for tracking individual models as they go through the system.

Frosted Ultra Detail Plastic

Frosted Ultra Detail plastic is a brittle acrylic material popular with model and miniature makers, great for moving parts like model trains. We enter a room of printers not much larger than office photocopiers. They have been named after The Golden Girls for their unique personalities.

Layer by layer, liquid acrylic plastic is deposited where the model is, and wax in the negative space as a support material: this is what allows interlocking and moving parts. Each layer is cured with UV light before moving onto the next. When the block of plastic and wax is complete, the wax is melted off in an oven to be reused, the model goes through an ultrasonic bath, and finally to QA and shipping when it’s dry.

The caveat of this process is that wax inevitably escapes the printer bed and gets into the belts, gears, and electronics, causing print quality problems and jams. Eleanor says amateurs who buy 3D printers often don’t estimate the amount of maintenance required to keep their machine operational and optimized… A service like Shapeways may be ideal for those who want to 3D print, without the hassle of upkeep.

Strong, Flexible Plastic

Whitney leads us into a room of massive bank-breaking industrial machines to show us the Selectively-Laser-Sintered (SLS) Nylon method Shapeways started with. Nylon powder is summoned through overhead tubes and deposited in a 1/10 mm layer in a very hot printer chamber. Then, a laser traces the design(s), fusing the particles together, and it’s onto the next layer.

The nylon powder that wasn’t zapped is the support material, allowing interlocking and moving parts (just like Frosted Ultra Detail plastic) and many models per build, without designing supports into the model.

24-48 hours later… ding! The “cake” is retrieved from the printer by a worker in protective clothing with a very nifty hand crank forklift. The worker brings another cake which has cooled for a day into the Breakout Room, and the comparison to a snowy dino dig is apt.

Finishing & Shipping

We walk by smaller machines that do different material, like Metallic Plastic/Alumide and Full Colour Sandstone. The sandstone method is essentially an inkjet print sandwiched between very thin layers of a gypsum and cornmeal binder and a Superglue-type sealant.

At the polishing and dying stations, the absorbent SLS Nylon plastic can be finished to order: dip-dyed with fabric/textile dye and tumbled with small ceramic pellets to a brilliant shine.

Models are inspected for quality and packaged for shipping, and Eleanor poses another invitation for optimization. For Canada, Shapeways currently offers UPS courier (fast, possible duty) and USPS parcel (slower, duty incl.)

Economics

The level of investment needed for a startup trying to revolutionize manufacturing is very different than a tech startup making software, says Eleanor. Phillips’ support was what started it all, just as the New York City Economic Development Corporation and former Mayor Bloomberg helped Shapeways find their current building and some utilities.

When it was estimated a 28 mm figurine would cost $10-$20 depending on the material, Henrik Rydberg, Director of UX responded with the available alternatives: industrial manufacturing or buying and maintaining a desktop printer. Mass manufacturing uses plates or an injection mold, which has a large one-time setup cost, but relatively minor material costs after. This is why plastic chairs which have been manufactured in China for 40 years are so cheap.

At Shapeways though, prices are set “until, like, 5000 things,” and even then, they would be very choosy. Both for the customer–for which traditional manufacturing may be better suited–and all the other customers expecting prompt service.

Shapeways had a Materials Engineer do a little Taylorism last summer to reprice SLS Nylon. Naturally, the proliferation of 3D printing and new entrants to the market will drive prices down. Henrik says another factor is labour, “There are so many hands involved… your product is touched by many people… About 10 people.”

Technology & Craft

It’s no secret there is some aversion to computer-assisted processes in many artisanal communities. But why wouldn’t there be, when anyone can just download a Venus de Milo (or your design) and click “Print?” Nobody would know. That’s why the handmade is the true mark of authenticity.

Eleanor tells us about an upcoming craft, business, and “Makers” conference that wasn’t interested in a panel discussion about bringing together handmade and high-tech. Meanwhile, I’m looking at last year’s conference photos… I see some fancy looking swiss Bernina sewing machines with built-in LCD displays. I see all manner of factory-produced promotional products, not to mention all the products and materials freighted across the ocean. I see smartphones, Macbooks, DSLRs, and audio equipment to document and amplify the event. Who I don’t see are young people; possibly this generational rift is intentional.

It is a fallacy that incorporating lasers, 3D printers, and even hand-assembled circuits into projects invalidates “craft” and somehow protects you from the future. The most inventive and successful artists and artisans take a pragmatic approach to mediums. Having the option to reproduce a popular design or do quick customization through a high-tech production method also helps the individual or team become a sustainable enterprise and keep doing what they love.

David McClyment, one of Canada’s great contemporary artists and a former teacher of mine liked to challenge us that Leonardo da Vinci would have used the camera if it had been available to him. Indeed, Tim’s Vermeer (2013) functionally proves the compelling theory that the renowned Dutch painter developed an optical system to achieve his “superhuman” photorealism.

Environmental Impact

When asked about post-consumer, biodegradable materials, Eleanor says Shapeways is primarily focused on efficiency until eco materials are ready for industrial prime time. The copious amounts of nylon powder used in their SLS Nylon method is chemically sound and much of it is reused.

There is a filament being developed in Amsterdam from discarded plastics they are looking into, but you can also prototype with an eco-friendly consumer printer, and order the final piece from Shapeways. Makerbot & Ultimaker home printers use PLA filament (a cornstarch-based material), instead of petroleum-based ABS filament, which is why they smell like popcorn.

“One of the environmental impacts I see in 3D printing is, first: we don’t create a product that somebody doesn’t want. There’s no storage of products that never sold,” says Henrik, “The second impact is as the future wills it, we get to be more and more localized manufacturing … I hope that one day we will have enough manufacturers so that you have one in your home city, so that the logistics goes away. Because that’s a big, big environmental savings.”

Eleanor’s Career

Eleanor Whitney worked in art museums, then a non-profit artist funder. “My goal was always to empower creative people, to get what they were making out there, whether it was through a public program or a museum, or by raising money so they could realize their vision,” says Eleanor, “But for me personally, I felt that the non-profit world was moving too slowly.”

“I graduated college 10 years ago, and the idea that you could work in tech, in New York, as a non-technical person was really not something that you would think about. So I went towards arts and culture, and education, and what I have seen really in the last five years is that tech is a huge, exciting industry here, it’s creative, and you don’t have to work in a technical role.”

At the end of our tour, Eleanor revealed she was leaving Shapeways in 2 weeks, moving to Marketing and Community Manager position at Dev Bootcamp, an immersive art and code education program. She extends an open invitation to contact her about career advice or about working in startups.

Lee Saynor is a Digital Futures undergrad at OCAD University. The keystone of Atelier II – Collaboration was a week-long field trip in New York City, where the class visited some of the most important people and organizations in creative technology. Thank You Eleanor and Henrik!

Leave a Reply